PE Sewer

PE Sewer Pipe Systems

PE sewer pipe and fittings are manufactured to AS/NZS 4130 using PE100 high density polyethylene material that is co-extruded with a dark external colour and a white/light internal colour. This system is designed specifically for the waste water industry and is best suited to gravity sewer and drainage applications.

The dark external layer (black/white stripe or dark grey) provides impact and UV resistance, while the white/light coloured internal layer provides good reflection for manual and video inspection purposes.

Sewer fittings are factory fabricated and welded using PE sewer pipe and moulded fittings as required.

The spigot ended pipes and fittings are joined by fusion welding, to ensure a fully sealed system, using either the butt-weld or electrofusion processes.

Standard |

AS/NZS 4130 (Pipe)

AS/NZS 4129 (Fittings) |

|---|---|

Size Range |

DN 110 - DN 315 (Sewer Reticulation)

DN 400 - DN 1200 (Large Trunk Sewers) |

Materials |

PE100 Polyethylene AS/NZS 4131 |

Pipe Class |

SDR 21 (standard)

SDR 17, SDR11 (stiffer classes made to order) |

Lengths |

6m, 12m Lengths |

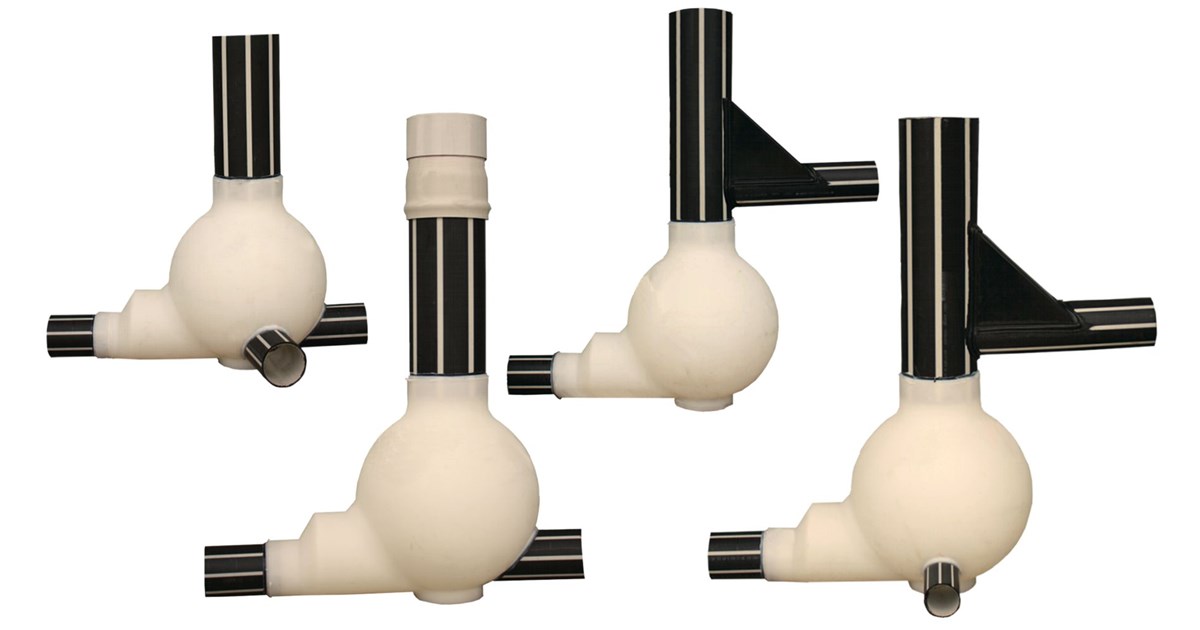

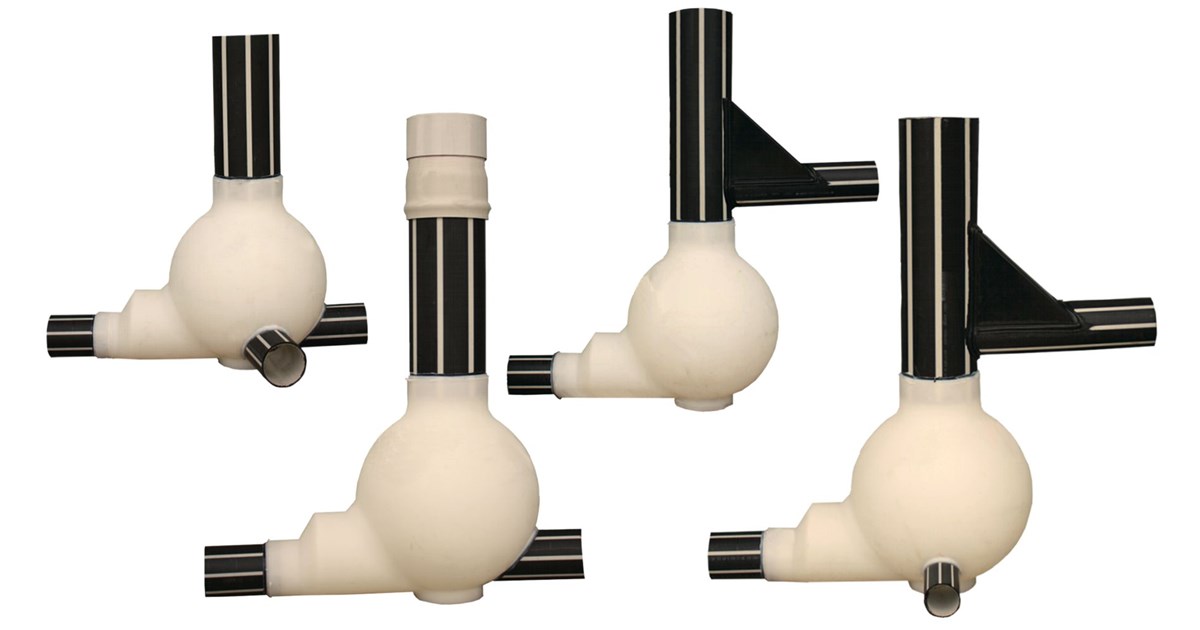

PE Maintenance Shafts

We offer a range of Maintenance Shafts that have been appraised by WSAA and approved for use by the major water authorities.

Where approved, maintenance shafts are quick and easy to install making them an ideal replacement for traditional manholes.

Maintenance shafts can be configured with up to 3 inlet junctions at varying angles and inverts; and can include riser pipe junctions for larger drop connections.

Standard |

WSAA Appraised |

|---|---|

Pipe Sizes |

DN 110, 160, 250, 315 & 400 |

MS Base |

2 way (1 Inlet) M&F or F&F

3 way (2 Inlets) M&F or F&F 4 way (3 Inlets) M&F or F&F |

Jointing |

Long stub for fusion welding |