PE Pressure

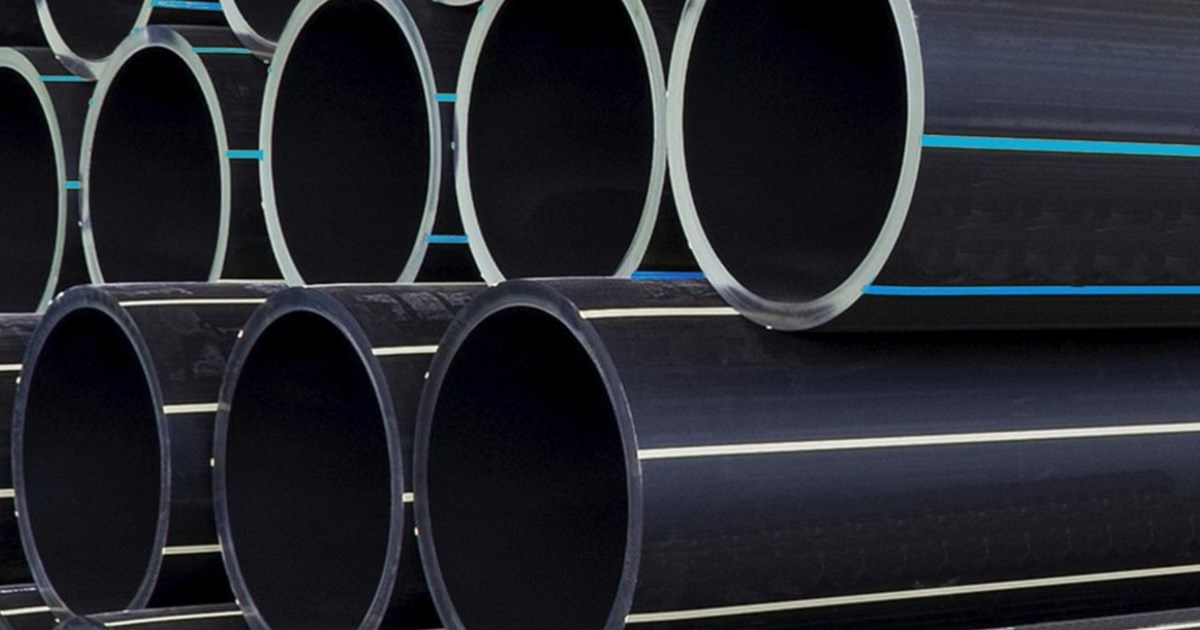

PE pressure pipe systems are manufactured using PE100 high density polyethylene material. Other lower class materials are available but are generally not used for pressure applications.

Polyethylene is a very versatile material that has exceptional corrosion and chemical resistance; high impact resistance; flexibility, weather resistance and can be installed in trenched and trenchless applications.

PE Pipes and fittings can be joined using an economical mechanical compression joint for smaller diameter pipes or by fusion welding a joint using either the butt-weld or electrofusion processes.

PE Pressure Pipe

PE pressure pipes can be manufactured in a wide range of pressure classes and sizes.

The benefits of PE100 material, make it an ideal product choice for many applications such as potable & non-potable water systems, mine water & slurry systems, gas pipe systems, compressed air systems, submarine pipe systems and industrial process pipework.

Pipes can be made in straight lengths (all sizes) or coils (small diameter pipes) with colour coded stripes for application identification.

Standard |

AS/NZS 4130 |

|---|---|

Size range |

DN 20 - DN 1200 |

Material |

PE100 Polyethylene (Water/Sewer),

PE80/100 (Gas), PE80 (Electrical/Communications |

Pressures |

PN4 to PN25 (at 20deg C) |

Lengths |

6m, 12m and 20m Lengths |

Coils |

25m - 200m Coils up to DN160 |

Colours |

Black, Blue, Purple, Cream, Yellow, Orange and White |

PE Electrofusion Fittings

As an alternative to butt welding, the PE Electrofusion process provides a unique socket fusion welded system for PE pipes and fittings.

The PE EF fitting has socket ends with embedded heating elements, that require an electrical input from a welding machine to melt the surface between the fitting socket and pipe spigot to form a homogenous welded joint.

Standard |

AS/NZS 4129 |

|---|---|

Size Range |

DN 20 - DN 800 |

Materials |

AS/NZS 4131 |

Pressures |

PN 16 (Standard),

PN 10 & PN 25 (Limited range) |

SDR Range |

EF Fittings are compatible with a range of SDR ratings. Refer data sheet |

Fusion Welding |

Refer PIPA Guideline POP001 for Electrofusion Jointing of PE Pipes and Fittings. |

Technical Documents

PE Spigot Fittings

Available in a wide range of configurations, PE spigot fittings can be joined to PE pipe using compression fittings, for smaller diameter pipes, or by fusion welding the joint using either the butt-weld or electrofusion processes.

Spigot fittings are available in short or long spigot options; the short spigot is suitable for butt welding only, and the long spigot is suitable for both butt welding or electrofusion welding.

Standard |

AS/NZS 4129 PE Fittings

AS/NZS 4130 PE Pipe AS/NZS 4131 PE Materials |

|---|---|

Size Range |

DN 20 – DN 1200 (varies by product type) |

Materials |

AS/NZS 4131 Polyethylene materials |

Pressures |

PE100 PN 16, PN 10, PN 20, PN 25 |

Spigots |

Short Spigot - Suitable for butt welding only

Long Spigot - Suitable for butt welding and electrofusion welding |

Technical Documents

PE Stub Flanges & Rings

PE Stub Flanges and Backing rings provide a flange connection point in PE pipe systems.

Stub flanges are available in a range of pressure classes, with either a short spigot for butt welding or a long spigot for both butt welding or electrofusion welding.

Backing Rings are available in a range of materials and can be drilled to suit any Australian or international standard.

Standard |

AS/NZS 4129 PE Fittings - Flanged |

|---|---|

Size Range |

DN 20 – DN 1200 |

Materials |

Stub Flanges - AS/NZS 4131 PE100 Polyethylene materials

Backing Rings - AS/NZS 4331.1 Metallic Flanges (ISO 7005-1) |

Pressures |

PE100 PN 16, PN 10, PN 20, PN 25 |

Spigots |

Short Spigot - Suitable for butt welding only

Long Spigot - Suitable for butt welding and electrofusion welding |

Flange Drillings |

AS 2129, AS 4087, ANSI 150 B16.5, ISO 7005 |

Backing Rings |

Refer to PIPA Guideline POP007 Metal Backing Flanges for PE, for backing ring details and flange joint installation |

Technical Documents

PE Restraint Products

PE Restraint products are available in couplings, flange adaptors, end caps and valves; and are suitable for potable water, non-potable water and sewer applications.

The restraint end incorporates a mechanical grip ring and sealing system that provides a full restraint connection for PE pipes and fittings, that is quick and easy to install.

Application |

Potable, non-potable and sewer systems |

|---|---|

Features |

Full restraint fitting for joining PE Pipes |

Size Range |

90 to 355 OD |

Pressure |

PN16 (Water) |

Jointing |

A support liner is required for thin wall PE pipes <3mm and low pressure pipes. |

Technical Documents

PE Compression Fittings

Available in a wide range of configurations including joiners, bends, tees, reducers and saddles; PE compression fittings offer a cost-effective solution for joining small diameter PE pipe systems.

Simply push pipe into the fitting socket and tighten to form a pressure rated compression joint.

Fittings are available with BSP ends for connections to other threaded components and with Adaptors for connection to other materials such as copper and steel.

Standard |

AS/NZS 4129 |

|---|---|

Size Range |

DN 15 - DN 160 |

Materials |

Polypropylene Body NBR Seals |

Pressures |

PN16 (DN16-DN125), PN10 (DN160) |

Application |

Suitable for potable water systems |

Technical Documents

PE BSP Threaded Fittings

BSP threaded fittings offer a great solution for offtakes on PE pipe systems. These can be joined to any BSP end on PE compression or spigot fittings.

Available in materials such as poly, brass and stainless steel making them ideal for a wide range of applications.

Size Range |

DN 6 to DN 100 |

|---|---|

Materials |

Poly- Polypropylene or Glass Reinforced Nylon to ISO 7.1

Brass- DR brass compliant to AS3688 SS 316- Stainless Steel Gr 316 to ISO7.1 Class 150 |

Pressures |

PN16 Poly fittings DN 6 - DN50. Brass and SS fittings all sizes,

PN12 Poly fittings DN65 PN10 Poly fittings DN80 – DN100 |

Certification |

AS/NZS 4020 - Suitable for potable water applications |

Technical Documents

PE Tools and Accessories

CIVILPIPES offer a comprehensive range of tools, equipment and accessories for the installation and jointing of polyethylene pipes and fittings.

This includes tools and equipment for pipe cutting, pipe and saddle preparation, mechanical jointing, fusion welding, pipe shut-off, pipe clamping and pipe rounding tools.

COMPRESSION TOOL |

Wrenches, chamfering and de-burring tools |

|---|---|

PIPE CUTTERS |

Scissors, ratchet and rotational cutters

Guillotines |

FUSION WELDING |

Pipe clamps and top load clamps

Hand scrapers and rotational scrapers Electrofusion machines Debeading tools |

PIPE ROUNDING |

Squeeze off tools

Rerounding clamps Rounding tools and clamps |